SB Time Capsule

- Jodi Brunner

- Oct 7, 2025

- 8 min read

Strictly Business is proud to introduce a new feature.

The Strictly Business Time Capsule will be both a celebration of where the North Country business community has been, where we are now and an invitation to imagine where the next decade may lead. In revisiting businesses from our archives, we will examine what has endured, what has transformed and how the visions of yesterday shaped the realities of today. For some, the journey has meant steady expansion and generational leadership. For others, it has meant navigating closures, reinventions or new ownership. Each story will be a reminder that business is never static—it is a living, evolving reflection of people, community and time.

THEN: 1995 - BOMBARDIER

Making Our Future

By Mary Carpenter

When the first rail car shell arrives at Bombardier’s new Plattsburgh facility in late August, the community will breathe a collective sigh of relief. The shoring up of the local economy, weakened by the imminent closure of Plattsburgh Air Force Base, will have begun.

Bombardier, a world leader in the manufacture of transportation and aerospace equipment, and motorized consumer products, is a company every community would like to have in residence.

Bienvenue, Bomba

It has been less than a year since then-governor Mario Cuomo stood on the steps of Plattsburgh’s City Hall with officials of Bombardier, as they announced their plans to build a second U.S. rail car assembly plant. Recognizing their need for a facility to satisfy the Buy-New York clause of a newly won contract, Bombardier announced plans to complete the plant by August 1995. While skeptics may have doubted the company’s ability to meet that ambitious deadline, the plant was completed on schedule. Construction was supervised by AXOR, the Canadian company that had built several of Bombardier’s corporate facilities world-wide. All work on the Plattsburgh plant, except for the steel structure which was built in Quebec, was subcontracted to local firms. Over 95 percent of the construction workers employed on the project were from the Plattsburgh area.

The early 1980s were boom times for the rail car industry because so few cars had been produced during the lean 1970s. Between 1983 and 1986, Bombardier fulfilled a billion-dollar contract for 825 cars for New York City. Since the contract was financed by the Canadian government, it was not subject to Buy-American or Buy-New York provisions. The cars were built in the company’s Vermont and Quebec plants, but marketing analysis showed the company that the majority of future market activity would be in New York State. A state con tract clause, developed during the Cuomo administration, requiring 25 percent New York content in each rail car purchase focused Bombardier’s attention on the Empire State and eventually on Plattsburgh.

“We realized more than four years ago that we would have to establish a New York plant if we were going to continue to build cars for the Metropolitan Tran sit Authority,” explains Bombardier’s Plattsburgh general manager David Cuttler. State budget constraints coupled with few rail car contracts postponed the company’s move.

When Bombardier began a serious state-wide search for the ideal New York location, it ruled out its subsystem plant in Auburn, as well as a number of other locations. “We believed the Plattsburgh area had the ingredients to help us remain cost competitive in our industry,” Cuttler continued.

At the time Bombardier knew it would likely win the Metro North contract, the closing of PAFB had just been announced. With its Barre plant to the southeast, its central corporate offices one hour away in Montreal, and a readily available workforce, Plattsburgh became the prime area of consideration.

“We were immediately impressed by the reaction of the people in this area,” Cuttler said. “It was apparent that they wanted to work with us.” Initially, Bombardier was looking for a facility that it could convert, and PAFB had a building the company believed would work for them. “We moved forward to finalize letters of intent, but unfortunately we could not close a deal with the Air Force,” Cuttler explained. “The city of Plattsburgh came up with an alternative. The new location, along with attractive financing, made it possible for us to locate here.”

Bombardier’s $7.5 million Plattsburgh facility, located off Wall Street, was built using the same plans as its Barre, Vermont plant. Starting out with 63,000 square feet of space, 120 employees, and one contract, today the Barre facility has expanded to I00,000 square feet and employs 300, down from a high of 500 in 1994. “We have built a state-of-the-art plant that will be able to expand to compete with anyone,” Cuttler said proudly.

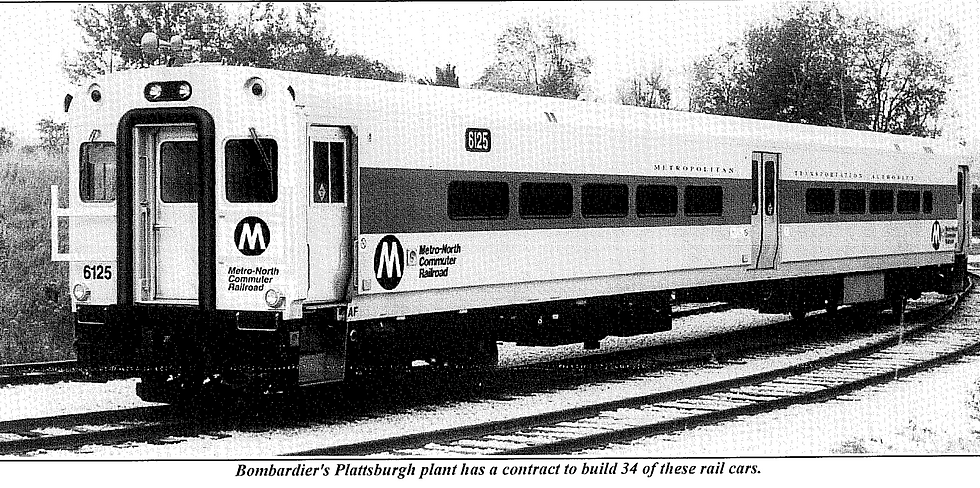

The Plattsburgh plant will start with a $43 million contract for 34 commuter cars for Metro North Railroad-with an option for 15 additional cars. The first two rail car shells will arrive in Plattsburgh on August 25. “Our job will be to install the interiors, integrate systems, and paint the cars. Each car will then be tested, made ready for the field, and shipped to the customer by rail,” Cuttler explained. “All we really have to do is put 10,000 parts in the right place at the right time.”

After the pilot cars are complete, the balance of the shells will arrive at a measured rate---one every six days, and then eventually, one every four days. Shipment will be at the same rate, until the contract is finished in the summer of 1996. If the option for additional cars is exercised within the next few months, the cars will be built in continuity. That will extend the plant’s work time by three more months.

By the end of August, Bombardier will have 50 to 60 people working. Full employment-between 120 and 150-should be reached by mid-October. Employees have been prescreened to identify an aptitude for hands-on work. Since June, the company has conducted two training classes on blue print reading, the use of tools, and basic assembly processes. Instructors from the Vermont Technical College conducted the classes at the BOCES training center in Plattsburgh using a training outline developed by Bombardier more than 15 years ago. For hands-on experience, students were bused to the Barre plant.

First hires were chosen from those who successfully completed the initial training class. “As we increase our work force, we will hire more people from that class, as well as people from our second training class,” Cuttler said, “When we find the right people, we put a lot of work into training them. We believe if we invest in our people, we will have a competitive company.”

The North Country business community is excited about Bombardier’s commitment to Plattsburgh and hopes run high that the international giant wi11 act as a magnet to draw other companies to the area. According to Cuttler, “Since Buy-New York provisions in contracts apply not only to Bombardier, but to our subcontractors as well, those who want to work with us will be in a better position if they are located in the state. There is potential for some suppliers to relocate to Plattsburgh, but it’s not a given. I don’t see it happening right away. When we get future contracts, I think we will see some suppliers come to the area. Vendors want to be close to the biggest players and Bombardier is the biggest player.”

When Cuttler visits Barre, he is often asked if Bombardier is planning to leave that Vermont town. “That is not our intention,” he explains. “The Barre plant has enough work to keep it busy until the first quarter of 1997. Our corporate goal is to operate the two facilities, but no one knows what is going to happen in the market.

“It is possible that cars for the Northeast Corridor project could play a very big role for both Barre and Plattsburgh. lf we sign a contract for those trains, it would be three years to deliver the first cars, and eighteen months to two years before activity would begin in the plants.

“From a growth stand-point, the New York plant will have the edge, since New York State is the largest consumer of rail cars and all state contracts contain a Buy New York clause.”

Asked what he sees ahead for Bombardier in Plattsburgh, Cuttler replies, “This plant has been built as an investment in New York State because we believe there is a future for us here. We would never have built a multi-million-dollar plant for just one contract. We were so confident that this plant would be successful, we would not have signed the deal with the city of Plattsburgh without an option to purchase the land adjacent to our plant now occupied by the city’s Water and Sewer Department. “With two plants, we will be better able to balance production to minimize swings in work load. We are working feverishly to see that when we finish this contract, there will be more work for this plant. But a contract is not a contract until it is signed and the ink is dry for a few days. We have to deal with reality, and reality, for now, is that we have work for our Plattsburgh operation until next summer.

“If the authorities bought rail cars based on need, it would take more capacity than we, and all of our competitors have. Right now New York State is operating approximately 8,000 rail cars. If you consider that the average life of a rail car is 40 years, the industry should be producing approximately 200 replacement cars each year for New York. During times of budget constraints, municipalities may not replace cars, but the need is still there. They will have to make up the deficit at some time. New orders will come. Maybe not this year, but they will c01ne.”

Cuttler continued, “Bombardier is renowned in the industry as the premier quality house. Our focus is to be better than any of our competitors. That philosophy is why we have averaged one third of the rail car market over the last ten years, and why recently that average has risen to 50 percent. We believe that if we maintain our one third share in the global market-which is expected to double in the next five years-it will justify our second U.S. assembly location. We will build our products on time, within budget and give our customers a quality product. We will make our own future.

NOW: 2025 - ALSTOM

Thirty years have passed since Bombardier began assembling rail cars in Plattsburgh. Over that time there has been both growth and change at the local plant including two physical expansions, increased employment and in 2021 a buyout by Alstom Transit, a global leader in the transportation industry.

Currently production at the Plattsburgh Wall Street plant is bustling, with two major railcar and locomotive contracts secured this year.

In July, Alstom was awarded a $2.3 billion contract from the New York Metropolitan Transportation Authority (MTA) for 316 new M-9A commuter railcars for the Long Island Rail Road (LIRR) and Metro-North Railroad. The contract also includes an option for an additional 242 cars for $1.5 billion.

The M-9A passenger vehicles, which will replace the MTA’s 40-year-old M-3 cars, will offer quieter, smoother and more reliable rides, and feature USB charging ports, space for wheelchairs, accessible restrooms, and two sets of extra-wide doors on each side of the car.

The bogies (undercarriages) for the M-9A will be produced in Plattsburgh with the assembly completed at Alstom’s Hornell, New York plant located in the southern tier.

In September, New Jersey Transit awarded Alstom an expanded $1.1 billion contract for 200 Multilevel III commuter railcars and 12 dual-power locomotives to be fully assembled in Plattsburgh. The award was an extension of a previous order for 174 cars Multilevel III railcars currently under production locally.

“These orders will bring years of work to the Plattsburgh plant with additional great jobs,” said Garry Douglas, North Country Chamber of Commerce president. “It is a direct testament to the clear satisfaction of these major customers with the great vehicles produced by Alstom’s Plattsburgh workforce and its suppliers.”

Comments